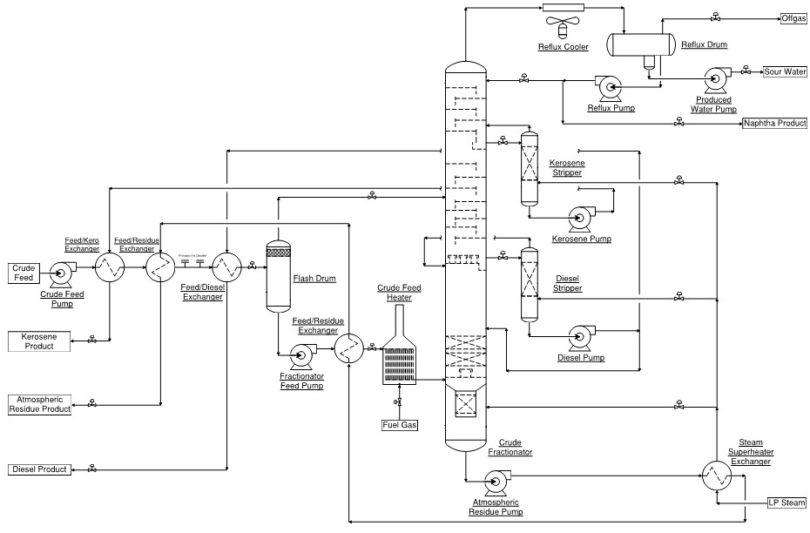

FRACTIONATION DESIGN CONSIDERATIONS

Internals

• Promote vapour/liquid contact for component separation and stripping

• Evaluate configuration and orientation to avoid issues and optimize distillate separation

Crude Heater

• Balance vapour / liquid ratio and outlet temperature

• Minimize hydrogen sulphide (H2S) generation due to thermal cracking

Contaminant Treatment

• Desalter maintains salt concentrations to prevent corrosion

• H2S removal or neutralization in naphtha product

Energy Recovery

• Optimize heat recovery from products

• Utilize pump around side draws for additional heating

Reflux

• Utilize a combination of methods to rectify vapours

• Overflash return to manage vapours from crude feed

Products

• Optimize draw rates maintain product purity to meet spec

• Enhance product recovery of distillate products